External users: registration to be carried out only through I-STEM portal

Additional information about sample and analysis details should be filled in the pdf form provided in the I-STEM portal under “DOWNLOAD CSRF”

Internal users (IITB): registration to be carried out only through DRONA portal

Additional information about sample and analysis details should be filled in the pdf form provided here.

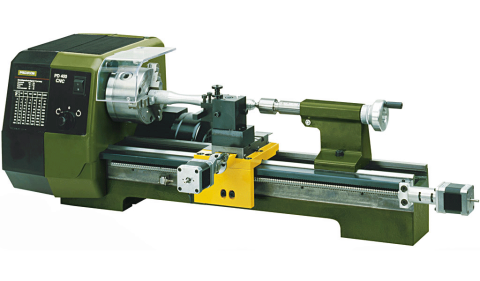

Make

Proxxon

Model

PD 400 CNC

Facility Status

Working

Date of Installation

.

Category

- Fabrication and Processing » Microfabrication

Booking Details

Facility Management Team and Location

Facility In Charge

Prof. Sandeep Kumar

Facility Manager

Swapnil P. Raut

Facility Operator

Swapnil P. Raut

Department

Energy Science and Engineering

Lab Email ID

swapnil.raut@iitb.ac.in

Facility Location

EN-517, 5th Floor Department Of energy Science and Engineering

Lab Phone No

00

Facility Features, Working Principle and Specifications

Facility Description

Facility Description

Facility Features

- High-precision computer-numerical-control lathe capability for turning, facing, boring, threading and other cylindrical operations. Hwacheon Asia Pacific Pte. Ltd.+2Rapid Prototyping+2

- Robust machine structure with automated tool‐turret (8-24 station) and steady‐state spindles, enabling high accuracy and repeatability in parts symmetric about an axis. Hwacheon Asia Pacific Pte. Ltd.+1

- Suitable for research, prototype fabrication and small batch production in metals (steel, aluminium, brass) and engineering plastics.

- Integrated CAD/CAM workflow: design to part with minimal manual intervention, enhanced productivity and consistency.

- Experienced technical staff support for job set-up, programming (G-code/M-code) and tool selection.

Features Working Principle

Working Principle

The CNC lathe machine operates on the principle of subtractive manufacturing of rotational parts:

- A workpiece is mounted in the spindle chuck and rotated about its axis.

- A cutting tool (or tool turret) is moved in one or more linear axes (typically X and Z) to engage and remove material from the rotating part. Hwacheon Asia Pacific Pte. Ltd.+1

- The machine control system executes a pre-programmed sequence (G-codes/M-codes) derived from the CAD/CAM tool-path, enabling operations like turning, facing, threading, grooving and drilling—often in a single set-up.

- Feedback systems and servo/ball-screw drives ensure precision, repeatability and minimal set-up error across jobs.

Body Specification

Specifications

- Max Turning Diameter: up to ~ 800 mm over bed. WMT CNC Industrial Co.+1

- Distance Between Centres: e.g., 1000 / 1500 / 2000 mm options. WMT CNC Industrial Co.

- Spindle Speed Range: e.g., 45–180 rpm / 180–750 rpm / 600–1600 rpm (depending on model) WMT CNC Industrial Co.

- Spindle Bore: e.g., Φ 80 mm or Φ 105 mm for through-hole options. WMT CNC Industrial Co.

- Turret: e.g., 8-24 tool stations, capable of milling/drilling attachments.

- Accuracy / Repeatability: ± 0.005 mm (typical for this class)

- Materials Supported: Aluminium, and engineering plastics.

Sample Preparation, User Instructions and Precautionary Measures

Instruction for Sample Preparation

- Sample material: Specify alloy (e.g., Al 6061-T6, SS 304), heat treatment state, and initial stock size (e.g., Ø50 mm × 300 mm long).

- Geometric tolerance: e.g., diameter tolerance ±0.02 mm, surface finish Ra-0.8 µm.

- Required quantity: single piece/batch of 5 / batch of 20, etc.

- Please provide a CAD file in IGES/STEP format, and any drawings or process notes needed for gripping, orientation, and final inspection.

Charges for Analytical Services in Different Categories

Usage Charges

Applications

- Production of shafts, spindles, piston rods, cylindrical flanges and bushings.

- Prototype machining for automotive, aerospace, energy, robotics and instrumentation – axisymmetric parts.

- Research experiments requiring custom work-holding, jigs and fixtures to test fluid/structural dynamics.

Sample Details

Chemical allowed

NA

Allowed Substrate

NA

Gases allowed

NA

Substrate Dimension

NA

Target dimension

NA

Contamination remarks

NA

Precursors/ Targets allowed

NA