External users: registration to be carried out only through I-STEM portal

Additional information about sample and analysis details should be filled in the pdf form provided in the I-STEM portal under “DOWNLOAD CSRF”

Internal users (IITB): registration to be carried out only through DRONA portal

Additional information about sample and analysis details should be filled in the pdf form provided here.

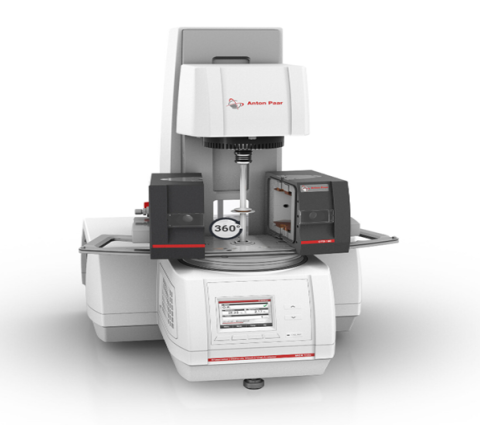

Make

Anton Paar Germany GmbH

Model

MCR 52

Facility Status

Working

.

Category

- Services » Service

Booking Details

Booking available for

Internal and External Both

Available Equipment/ Mode of use

Manual

Facility Management Team and Location

Facility In Charge

Prof. Lalit Kumar

Co-convenors

Facility Manager

Swapnil P. Raut

Facility Operator

Swapnil P. Raut

Facility Management Members

Department

Energy Science and Engineering

Lab Email ID

swapnil.raut@iitb.ac.in

Facility Location

EN-709, 7th Floor Department Of energy Science and Engineering

Lab Phone No

0

Facility Features, Working Principle and Specifications

Facility Description

Facility Description

Facility Features

- The facility houses the Anton Paar MCR 52 rotational rheometer, capable of advanced rheological testing (viscosity, viscoelasticity, shear stress/shear rate behaviour). Centre for Sophisticated Instruments+2Technology Networks+2

- High precision instrument with controlled shear stress/strain and rotational motion, enabling characterisation of complex fluids, suspensions, gels, pastes and non-Newtonian materials. TI Instruments+1

- Equipped with various measuring geometries (cone-plate, parallel plates, cylinder bob/cup) and temperature-control accessories (if available) to cover a wide range of rheological behaviours. Fluidan+1

- Suitable for research and development, formulation development, quality control, material science, chemistry, biofluids and energy-related flows involving complex rheology.

- Technical support from facility staff for test setup, sample preparation, geometry selection, temperature control and data interpretation (e.g., storage modulus, loss modulus, yield stress).

Features Working Principle

Working Principle

The rheometer works by applying a controlled deformation (strain) or load (stress) to a sample and measuring the resulting response (torque, displacement, shear rate). Wikipedia+1

- In a typical rotational rheometer (such as the MCR 52), a sample is placed between the measuring geometry (e.g., cone and plate or parallel plates). The upper geometry rotates (or oscillates) while the lower plate remains fixed. Shear is induced in the sample.

- The instrument measures the torque required to maintain rotation or oscillation and the angular velocity/strain. From this data, shear stress, shear rate and viscosity are derived. Technology Networks+1

- For viscoelastic materials, oscillatory tests measure storage modulus (G′) and loss modulus (G″) by imposing a small oscillatory shear strain and recording the stress response and phase angle between stress and strain. Technology Networks

- The instrument can thus characterise Newtonian fluids, shear‐thinning or thickening non-Newtonian fluids, yield behaviour, thixotropy, and other complex rheological phenomena. TI Instruments+1

Body Specification

Specifications

Make / Model: Anton Paar MCR 52 Centre for Sophisticated Instruments

Here are typical specification categories :

- Measuring range (torque) – e.g., [insert value] N·m

- Shear rate range – e.g., 0.01 to 1000 s⁻¹ (or as per model)

- Temperature control range – e.g., ambient to [1000] °C

- Measuring geometries supported – Cone/Plate, Parallel Plate, Cylinder Bob/Cup

- Minimum sample volume – e.g., a few mL (depending on geometry)

- Accuracy/repeatability – as per manufacturer data

- Control system: stress and strain controlled rheometer (rotational and oscillatory modes)

Sample Preparation, User Instructions and Precautionary Measures

Instruction for Sample Preparation

Sample Preparation:

- Ensure the sample is homogeneous, free of air bubbles or large particles if required for the test.

- Provide sample volume as required by geometry; clean geometry surfaces, apply sample carefully, avoiding air entrapment.

- Report material type, expected behaviour (Newtonian vs non-Newtonian), temperature range, and geometry preference.

- If testing at elevated or reduced temperature, ensure the sample is pre-conditioned.

User Instructions and Precautionary Measures

- User Instructions & Precautions:

- Book a slot via the facility booking system; provide sample details and test requirements ahead of time. Centre for Sophisticated Instruments

- Trained users only; facility staff will assist with geometry selection, test protocol set-up and run.

- Clean up the sample after the test, remove residues, clean geometry surfaces, and log any irregularities.

- Ensure safe handling of materials, especially if testing high‐temperature, corrosive or particulate-loaded samples.

- Avoid running tests beyond rated shear/stress limits; monitor for instability, slip or instrument alarms.

- Dispose of samples responsibly; keep geometry clean to avoid damaging the instrument.

Charges for Analytical Services in Different Categories

Usage Charges

Applications

Applications

- Characterisation of fluids and soft solids: paints, coatings, adhesives, slurries, gels, food products, biofluids. Technology Networks

- Shear‐thinning and thickening behaviour, yield stress and viscoelastic properties relevant to formulation, product development and process modelling. TI Instruments

- Material behaviour under deformation: polymers, polymer melts, composite resins, battery slurries, drilling fluids. Fluidan

- Quality control of rheological parameters in manufacturing and research contexts, and correlation to performance or processing behaviour.

Sample Details

Chemical allowed

NA

Allowed Substrate

NA

Gases allowed

NA

Substrate Dimension

NA

Target dimension

NA

Contamination remarks

NA

Precursors/ Targets allowed

NA