External users: registration to be carried out only through I-STEM portal

Additional information about sample and analysis details should be filled in the pdf form provided in the I-STEM portal under “DOWNLOAD CSRF”

Internal users (IITB): registration to be carried out only through DRONA portal

Additional information about sample and analysis details should be filled in the pdf form provided here.

.

Category

- Material Characterization » Thermal Characterisation

Booking Details

Rate of degree : 5°C /Min to 20°C /Min

Gas: N2 or Zero Air

Sample Form: Powder/Liquid

Facility Management Team and Location

email ID:- nagarkarss@iitb.ac.in,

Contact No:- 022-2576 7190

email ID:- darshansmhatre@iitb.ac.in,

Contact No:- 022-2576 4159

email ID:-head.chem@iitb.ac.in

Contact No:-02225767151

Facility Features, Working Principle and Specifications

Facility Description

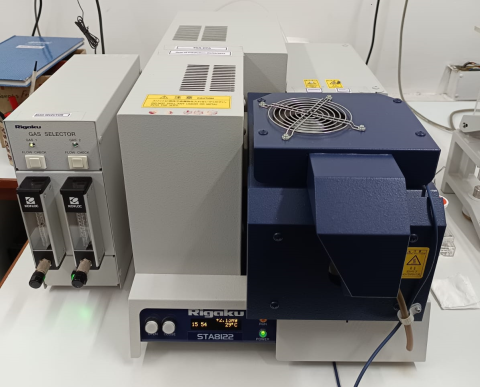

The Thermo Gravimetric Analyzer (TGA) measures a sample's change in weight as a function of temperature, enabling detailed analysis of reactions such as dehydration, thermal decomposition, evaporation, and oxidation. Additionally, Differential Thermal Analysis (DTA) detects endothermic and exothermic reactions during phase transitions, melting, crystallization, decomposition, and glass transition temperatures.

Rigaku’s TGA utilizes a horizontal differential triple-coil balance, designed to cancel out fluctuations and ensure highly accurate weight change measurements, providing robust data for thermal analysis.

In thermogravimetry, measuring the sample’s change in weight enables us to analyze the reaction temperature and the rate of weight change in reactions such as dehydration, thermal decomposition, evaporation, oxidation. Differential thermal analysis (DTA) measures the endothermic or exothermic reaction temperatures such in transition, melting, crystallization, dehydration, decomposition, oxidation and glass transition temperature.

Sample Preparation, User Instructions and Precautionary Measures

1) Sample form: powder (~10 mg).

2) The analysis can not be carried out if the temperature range and the heating rate are not specified.

3) Explosive, poisonous samples and samples giving rise to toxic/obnoxious gases/fumes on heating cannot be undertaken for Thermal Analysis.

4) The sample holders are of Aluminum (Al) and Platinum (Pt). The user must ensure that samples will not react with crucible materials during Thermal Analysis.

In order to safeguard the instrument from the damage it is absolutely essential that you must state the decomposition products associated with the heating cycle of your sample. Any functional group which might potentially explode, or form foams is strictly not allowed (Representative examples are Azide, Perchlorate, poly-nitro or nitrogen-rich compounds, etc.) Explosive, poisonous samples and samples giving rise to toxic/obnoxious gases/fumes on heating cannot be undertaken for Thermal Analysis.

Charges for Analytical Services in Different Categories

| TGA Instrument Charges | IIT Bombay | IITB TA | Other Academic Institutes | National Lab | Industries | Start up SINE | Monash IITB | SARC contries Academic | SARC contriesw Industries | Other Contries Academic | Other Contries Industries |

| Heating Program: Temp. 10 ℃ per Minute | |||||||||||

| RT- 600 ℃ | 400 | 200 | 800 | 2000 | 4000 | 2000 | 400 | 2000 | 4000 | 4000 | 8000 |

| RT- 800 ℃ | 500 | 250 | 1000 | 2500 | 5000 | 2500 | 500 | 2500 | 5000 | 5000 | 10000 |

| RT- 1100 ℃ | 800 | 400 | 1600 | 4000 | 8000 | 4000 | 800 | 4000 | 8000 | 8000 | 16000 |

Applications

TGA-DTA analysis