External users: registration to be carried out only through I-STEM portal

Additional information about sample and analysis details should be filled in the pdf form provided in the I-STEM portal under “DOWNLOAD CSRF”

Internal users (IITB): registration to be carried out only through DRONA portal

Additional information about sample and analysis details should be filled in the pdf form provided here.

.

Category

- Microscopy and Imaging » Confocal Microscopy

Booking Details

Melting and solidification

Customizable Image quality and rate

Facility Management Team and Location

Email: deepook@iitb.ac.in

Contact no. 022-2159-7647

Prof. S. Karagadde

Prof. M. M. Pande

Prof. A. K. Suresh

Prof. B. Kavaipatti

Facility Features, Working Principle and Specifications

Facility Description

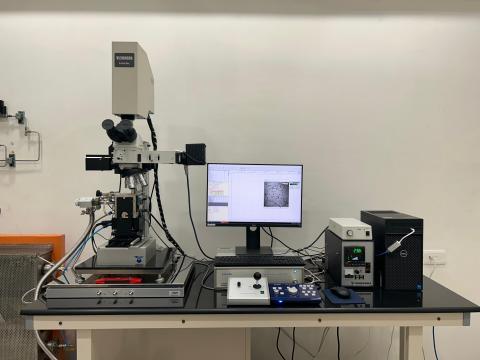

The high-temperature confocal laser scanning microscope enables material characterization under controlled thermal conditions. It features a He-Ne laser (λ = 632.8 nm, 1.5 kW) and IR heating via a 1.5 kW halogen lamp, reaching 1650°C. Operating in an argon atmosphere, it offers 0.5 μm resolution for real-time, in-situ microstructural observations.

In confocal microscopy, laser light is focused by an objective lens on to the object, and the reflected beam is focused onto a photo detector via a beam splitter. An image is built up by scanning the focused spot relative to the object, which is then stored in an imaging system for subsequent display. Through the use of a confocal pinhole, only light incident from the focal plane is permitted to pass through to the photo detector. Light not returning from the specific optical plane is blocked by the pinhole. Hence, an extremely thin optical section is created, providing a high-resolution image. Because thermal radiation is also blocked by the confocal pinhole, only the polarized reflection of the high intensity laser beam reaches the imaging sensor and a sharp image is produced. The use of pinhole optics increases the resolution such that with a 0.5 mm diameter beam,

Magnifications up to 500× at a resolution of 500 nm can be obtained, using a He–Ne laser with a wavelength of 632.8nm. In the system used a laser beam, 0.5mm diameter is reflected and scanned by an acoustic optical deflector in the horizontal direction at a rate of 15.7 kHz and a galvano mirror in the vertical direction at 60Hz. Specimens are placed at the focal point of a gold plated ellipsoidal cavity in an infrared furnace beneath a quartz view port.

Experimental Setup

- Laser source: He-Ne (Visible laser W.L. (λ)=632.8 nm)

- Heating source: IR heating by halogen lamp (1.5kW)

- Max temperature: 1650°C

- Inert Atmosphere: Argon gas

- Objective lens resolution: 50× TO 500×

- Controlled heating & cooling rate (3000°C /min) and

- Rapid cooling done by using controlled He gas flow rate

Sample Preparation, User Instructions and Precautionary Measures

Sample Specifications

The sample should be flat and mirror finish without any scratches.

- Cylindrical Sample (Large alumina crucible):

- Diameter: 6.0 mm

- Height: 3.9 mm

- Cylindrical Sample (Small alumina crucible):

- Diameter: 5 mm

- Height: 3.7 mm

- Rectangular Sample (Big crucible):

- Length: 5 mm

- Width: 4 mm

- Thickness: 3 mm

We shall accept online registration only through the IRCC webpage. If you need to cancel your slot, send an email immediately to with an explanation.

- Slots will be provided on a first-come-first-served basis.

- USB drives are strictly prohibited for copying data to minimize virus-related issues. You are requested to bring a new blank CD to transfer your data. All data must be transferred within 7 days of imaging. Without exception.

- Users must be present during the entire slot.

Charges for Analytical Services in Different Categories

users | New crucible | Reusing cleaned crucible |

| Internal User (IIT Bombay) | 2100 | 1300 |

| Lab TAs | 1850 | 1050 |

| IITB-Monash Students | 2100+ GST | 1300+GST |

| Academic Institutes | 2350+GST | 1550+GST |

| National Laboratories | 3100+GST | 2300+GST |

| Sine (letter from SINE reqd.) | 3100+GST | 2300+GST |

| Research Park (MSME) (letter from RP reqd.) | 3100+GST | 2300+GST |

| Research Park (Big industry partners) (letter from RP reqd.) | 3350+GST | 2550+GST |

| Industrial User | 3600+GST | 2800+GST |

- 18% GST will be applicable.

Applications

In-Situ Real-Time Studies

- Samples: metallic, semiconductor and non-metals

- In-situ real-time studies of phase transformations during heat treatment.

- Grain growth, sintering, precipitate formation at elevated temperatures.

- Inclusion behavior in molten liquid metals and phase transformations in solid-state metals.

- Solidification of metals and fluxes.

- Interaction between liquid metal, slag & refractory.

Sample Details

Sample form: solid / Pellet / Film on glass substrate